Granule Feeding System: At the heart of each granule filling machine lies a strong feeding system. This method is meant to successfully transport granular products through the hopper to the filling station.

MAP packaging typically will involve placing your packaged merchandise in environments with a controlled temperature, leaning towards colder temperatures.

What ever vegetable or fruit that you are working with, Henkelman has An array of vacuuming machines which can be upgraded with optional extras and accessories to fit your needs. Such as, tender air for the extra defense of vulnerable merchandise or perhaps the addition of gas flushing (MAP) for sliced fruit and veggies.

Omag S.p.A. is engaged in the look and manufacture of Mayonnaise & Ketchup packing machines. Our packaging machine is realized to match distinctive sauce packaging methods.

Sauce packing machines can be employed in filing and sealing tomato sauce in various containers. These machines is often personalized to match the viscosity and measurability from the product or service that needs to be crammed.

Load cells, sensors, or volumetric fillers are integrated to the system to watch and control the flow of granules, guaranteeing each package receives the precise food packaging machine manufacturers amount specified.

The system involved in sachet filling is similar to the pouch filling. The only change is the usage of sachets rather than pouches.

Sauce packaging machines streamline the whole packaging procedure, from filling to sealing and labeling. They are automatic machines which will fill and pack differing types of sauces into different containers, like jars, bottles, or pouches.

The modified fuel setting with 30 % carbon dioxide and 70 % nitrogen inhibited aerobic microflora. Having said that, it had no impact on coliform germs and yeasts and didn't preserve the sensory Attributes. Laminated foil with a further flow-pack vacuum protecting film decreased the oxidative procedures and prevented the development of mould fungi, Therefore expanding the shelf-life of butter which has a lower Preliminary bacterial contamination.

Why Chitale made a decision to MAP mithai when regular brick and mortar have been profitable for quite some time?

Weighing Mechanism: Precision is non-negotiable when it comes to filling operations. Granule filling machines hire refined weighing mechanisms to exactly evaluate the desired quantity of products.

1. Security and safety Sauce food packaging machine manufacturers packaging requirements uperization, which requires machines to help keep workers Harmless. Automated packaging machines are excellent to ensure the safety and performance of creation.

Utilizing MAP we can easily pack 200-250 gms simple retail units which might be attractive and compact to Exhibit on retail shelves,easy to acquire and consume by using stores.

These vacuum packaging machines are certainly not proposed to be used with retort or Mylar® packaging; instead, we suggest selecting from our wide variety of vacuum packaging baggage for ideal benefits! Retort and Mylar® packaging calls for Exclusive plastic and foil laminated pouches to seal food safely and securely.

Neve Campbell Then & Now!

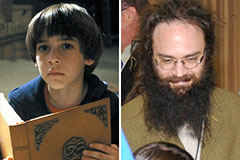

Neve Campbell Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Destiny’s Child Then & Now!

Destiny’s Child Then & Now! Michelle Trachtenberg Then & Now!

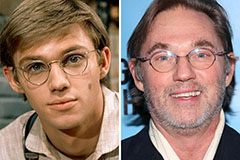

Michelle Trachtenberg Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now!